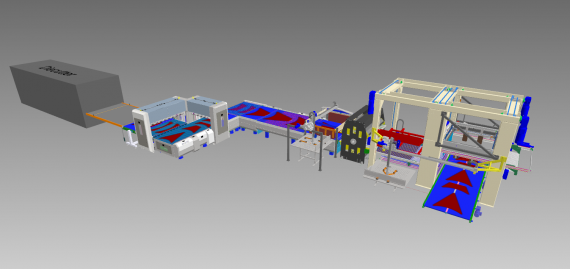

Avantar - the digital twin of the Avanti Conveyors Pegasus separator and palletiser

Avantar is the digital twin of the Avanti Conveyors Pegasus separator and palletiser.

A digital twin is a virtual representation of a physical object or process. The concept of digital twins is attributed to Michael Grieves, then of the University of Michigan, in 2002, but the first practical digital twin originated from NASA to try to improve their spacecraft simulation in 2010. Avanti Conveyors’ software engineers worked in conjunction with Autologic to create Avantar using Emulate 3D from Rockwell Automation.

Palletising and separating is a complex process to optimise the configuration of the die with the configuration of the load on the pallet, which affects the die-cutter’s performance. Historically this has been addressed by using tables or operator experience. This approach can be a bit erratic in understanding a palletiser’s performance. Estimated job run times can therefore be widely off the mark and scheduling workload is unpredictable.

Avanti Conveyors has developed a system called Avantar, which is the digital twin of the Pegasus separator and palletiser. A digital mimic of every action of the separator and palletiser has been created. The PLC code emulates all of the actions on Pegasus and can calculate the performance of the line. Line performance can also be emulated prior to installation, which results in faster start-up times.

The Pegasus Separator Palletiser was launched at FEFCO in 2017 to overcome the problem whereby converting machines were unable to run at full capacity due to constraints with existing separators or palletisers. Bottlenecks in the production flow have been beaten by Pegasus.

Avanti Conveyors are able to use this 3D virtual environment to demonstrate that Pegasus is the fastest separator palletiser in the market. Customers will be able to see how product flows through the machine and where time can be saved and manual handling can be avoided. A complete walk-through of the machine allows for our customers to see the full functionality of Pegasus and to see how it could cope with their product mix.

Much like learning to fly a spacecraft before going into space, Pegasus operators will be able to learn how to run Pegasus before the physical machine is on site. Emulators are a proven tool in training as changes can be made to stock, sizes and environment. The real-time responses of the trainees can then be monitored and training requirements modified. This process avoids the costly, time-heavy use of stock and machine, which is often running 24/7 and an interruption to production is not possible. This digital twin also allows operators to repeat tasks until they are comfortable knowing that they have fully understood the functionality of Pegasus. Individuals learn in different ways and having a virtual 3D environment will be another element in the trainer’s toolkit. Testing can also be integrated as a part of a continuous development training programme or as part of the interview process.

Click here to hear more about Avantar.

Please contact us to find out more about this innovative new product.

Video credit: FEFCO